Item Info

Source: Automobile Reference Collection

Notes:

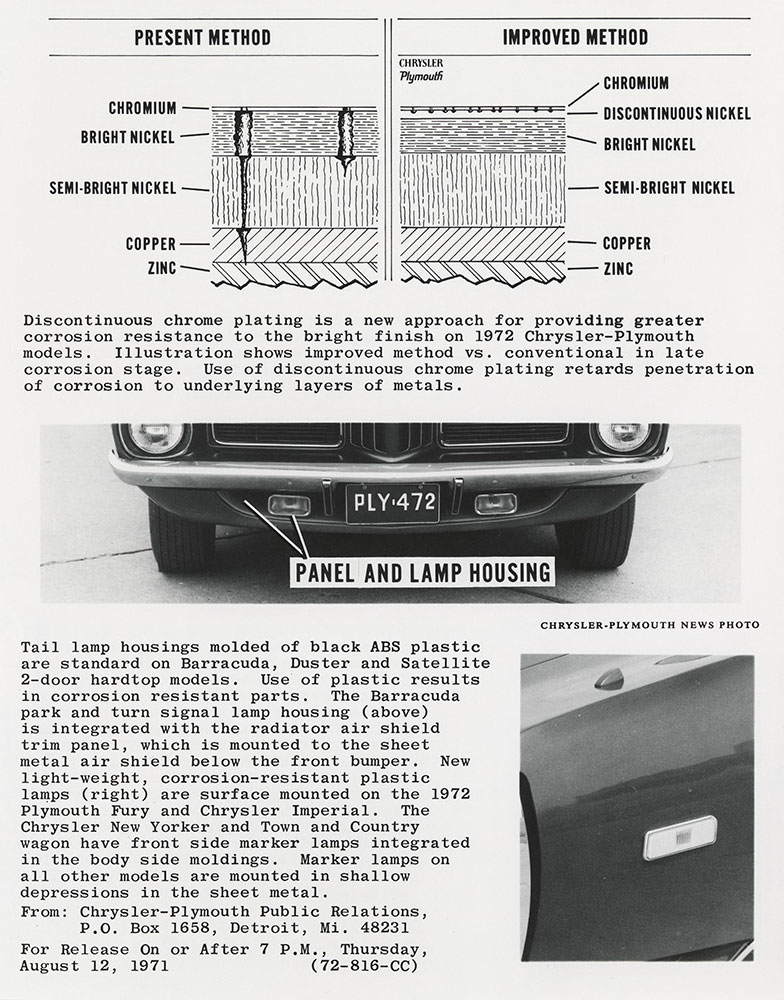

Top Left Illustration:

Present Method (top to bottom): 1) Chromium 2) Bright Nickel 3) Semi-Bright Nickel 4) Copper 5) Zinc

Top Right Illustration:

Improved Method: 1) Chromium 2) Discontinuous Nickel 3) Bright Nickel 4) Semi-Bright Nickel 5) Copper 6) Zinc

Discontinous chrome plating is a new approach for providing greater corrosion resistance to the bright finish on 1972 Chrysler-Plymouth models. Illustration shows improved method vs. conventional in late corrosion stage. Use of discontinuous chrome plating retards penetration of corrossion to underlying layers of metals.

Tail lamp housings molded of black ABS plastic are standard on Barracuda, Duster and Satellite 2-door hardtop models. Use of plastic results in corrosion resistant parts. The Barracuda park and turn signal lamp housing (above) is integrated with the radiator air shield trim panel, which is mounted to the sheet metal air shield below the front bumper. New light-weight, corrosion-resistant plastic lamps (right) are surface mounted on the 1972 Plymouth Fury and Chrysler Imperial. The Chrysler New Yorker and Town and Country wagon have front side marker lamps integrated in the body side moldings. Marker lamps on all other models are mounted in shallow depressions in the sheet metal.

Chrysler-Plymouth Public Relations

Tools

- Pan and Zoom

- Cite

- For a high-resolution copy of this image contact the AACA Library.